RESEARCH AND DEVELOPMENT CENTER

-

- Electronic Hardware Design

- Microwave and RF design(Within METU technocity)

- Software development

- Teting and certification

- Optical design and analysis

- Mechanical design

- Steel structure design

ELECTRONIC R&D SKILLS

-

- VHDL FPGA ASIC design and verification

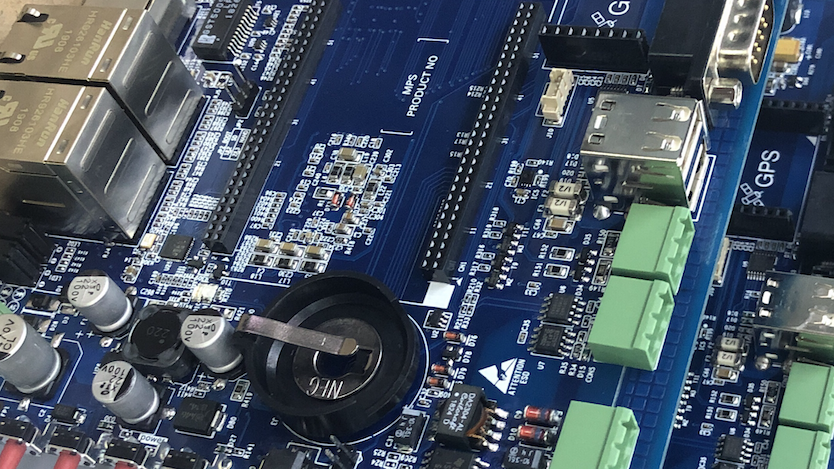

- 8-bit, 16-bit, 32-bit CPU/DSP board and peripheral card design

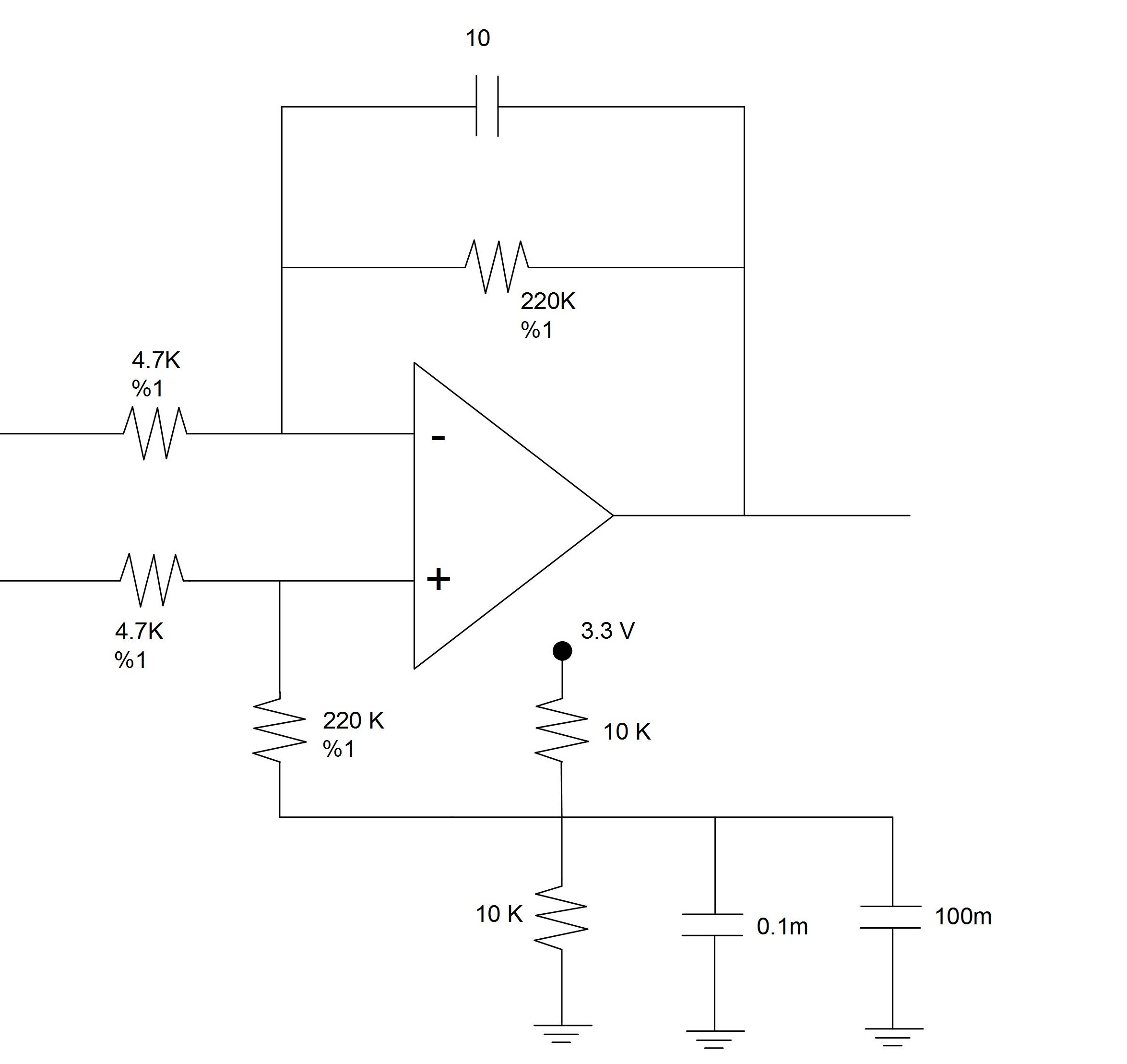

- Amplifier and filter designs

- Low noise amplifiers for IF band and instrumentation

- Switch mode power supply designs

- Signal process circuits

- Circuit designs and application development with digital signal processors(DSP)

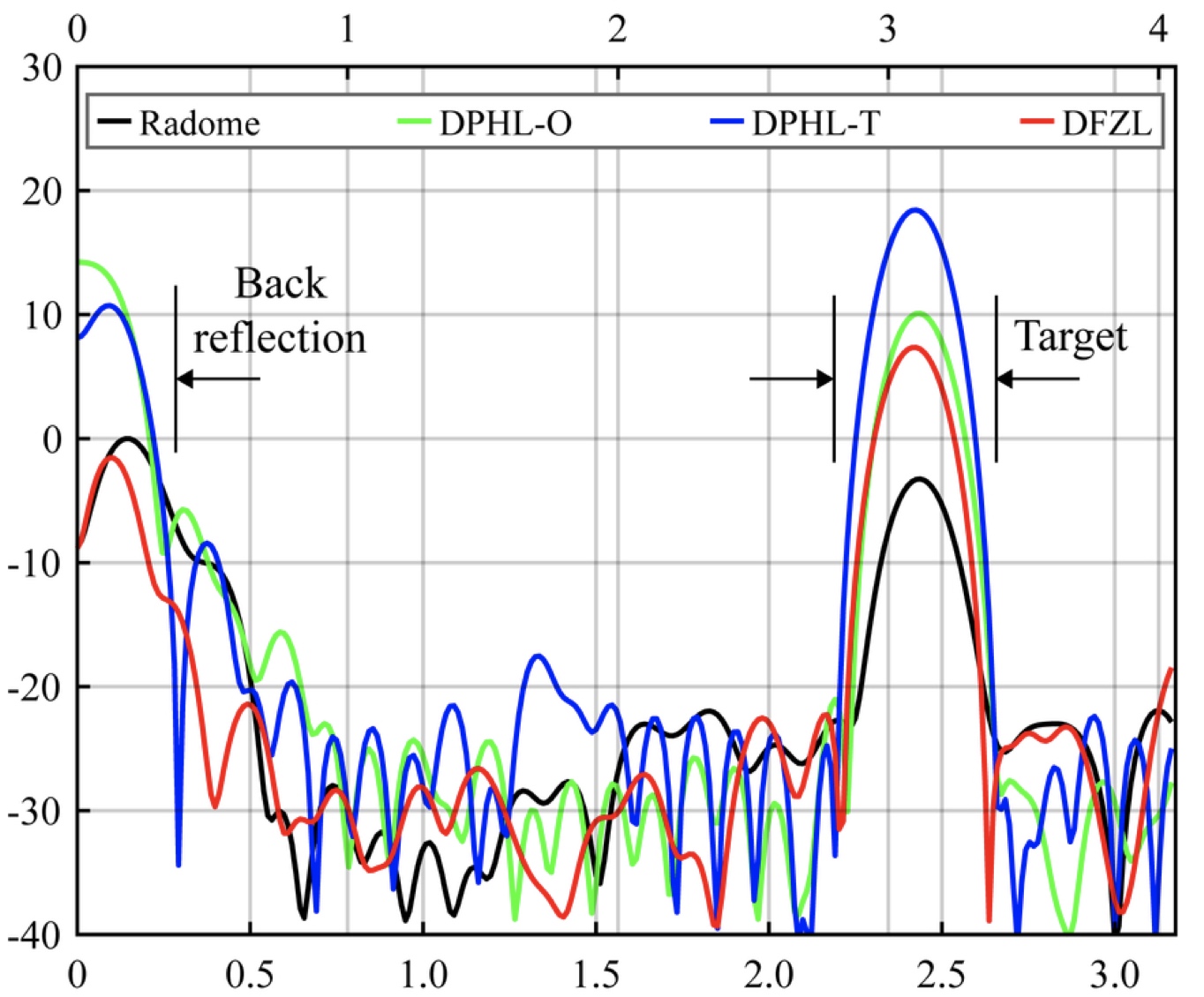

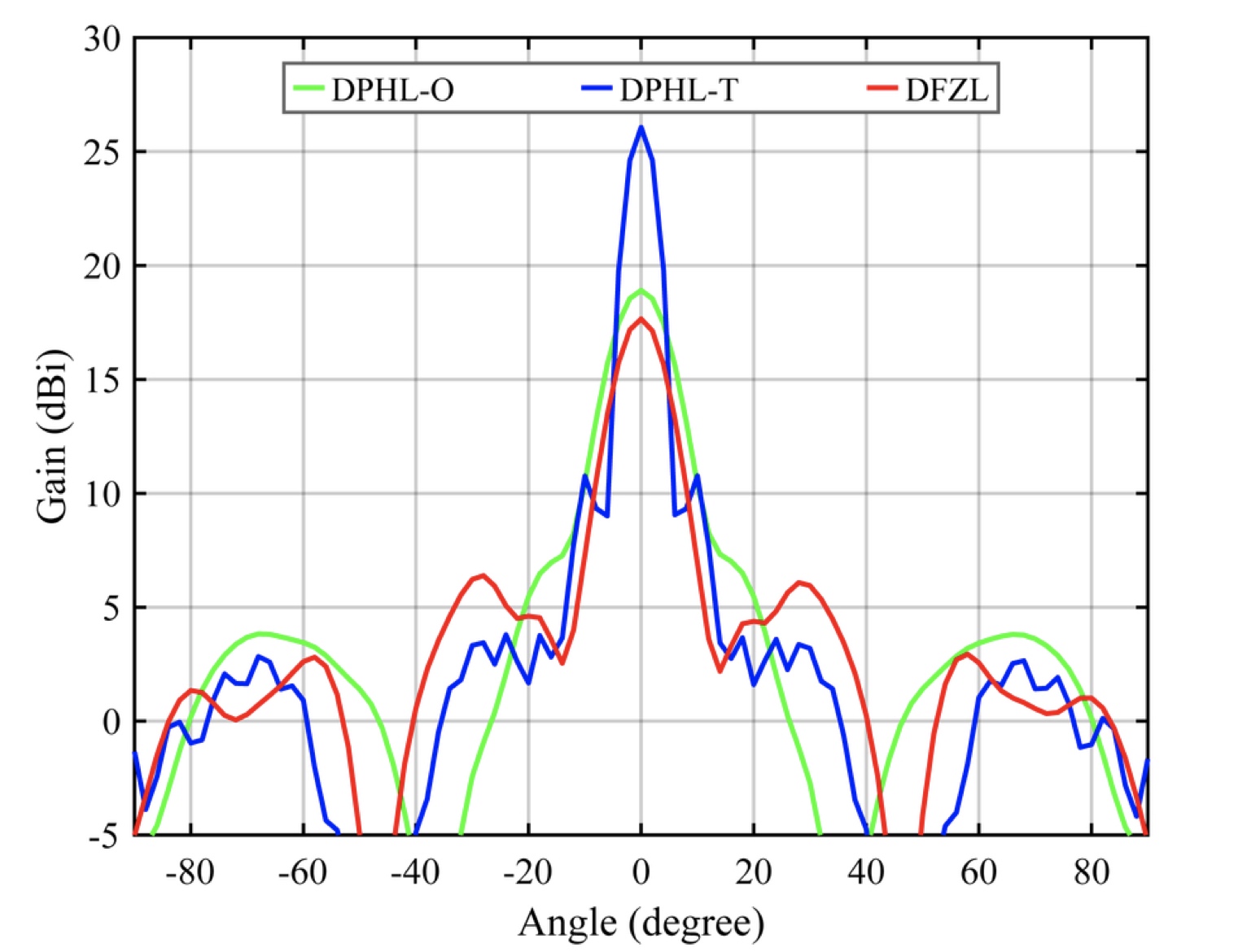

- Design, simulation and verification of signal processing algorithms for radar applications

- Embedded software development

- Real-time and embedded operating systems applications, uC/OD-2, VxWorks, TI-RTOS, Linux

- TCP/IP Stack, profibus, modbusTCP, OPC-XML, NTCIP developed within the company

- The first certified software profibus application in the world

- CPLD and FPGA designs

- Fiber optic Ethernet switches suitable for industrial temperature range

- VHDL FPGA ASIC design and verification

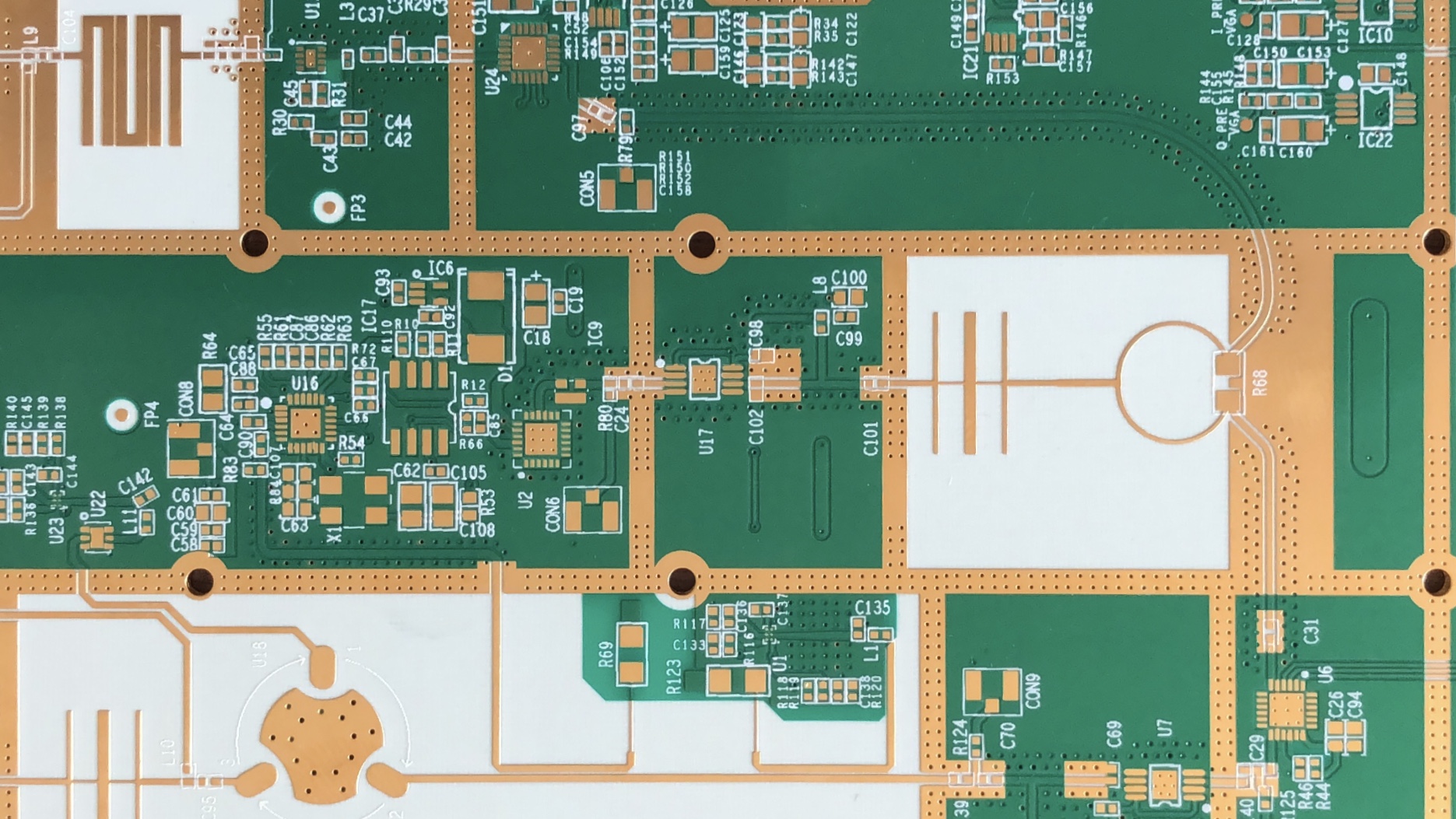

MICROWAVE AND RF SKILLS

-

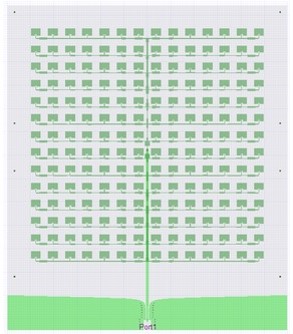

- HFSS based antenna design and simulation

- Microwave electronics designs

- Design and implementation of K-Band, W-Band design frequencies multi-node ISM Band frequency hopping RF system

- 24 Ghz microstrip patch antenna array design for radar applications

- 24 Ghz microwave front-end design for radar applications

SOFTWARE DEVELOPMENT SKILLS

-

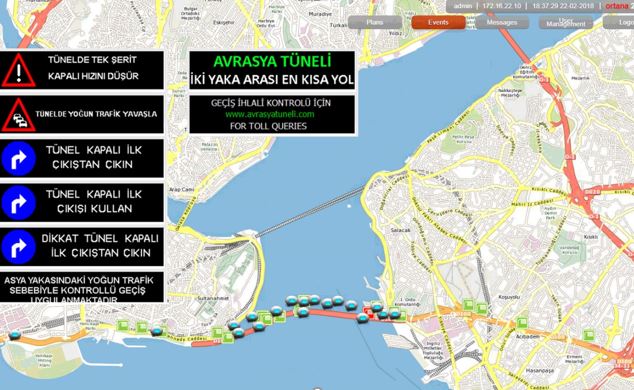

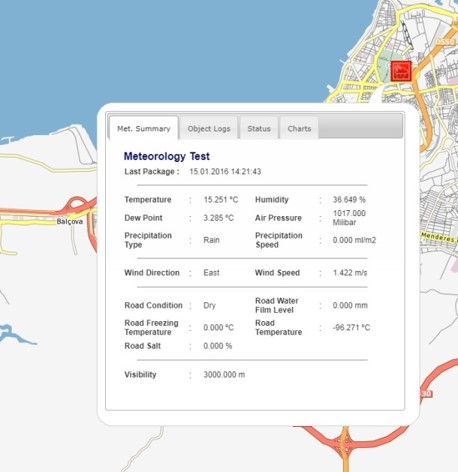

- Redundant cluster softwares

- Web based distributed command & control systems (graphical interfaces)

- Host system interface based on XML

- Mission critical systems (OPC, Cobra vb.)

- In-house implementation of various industrial standard protocols

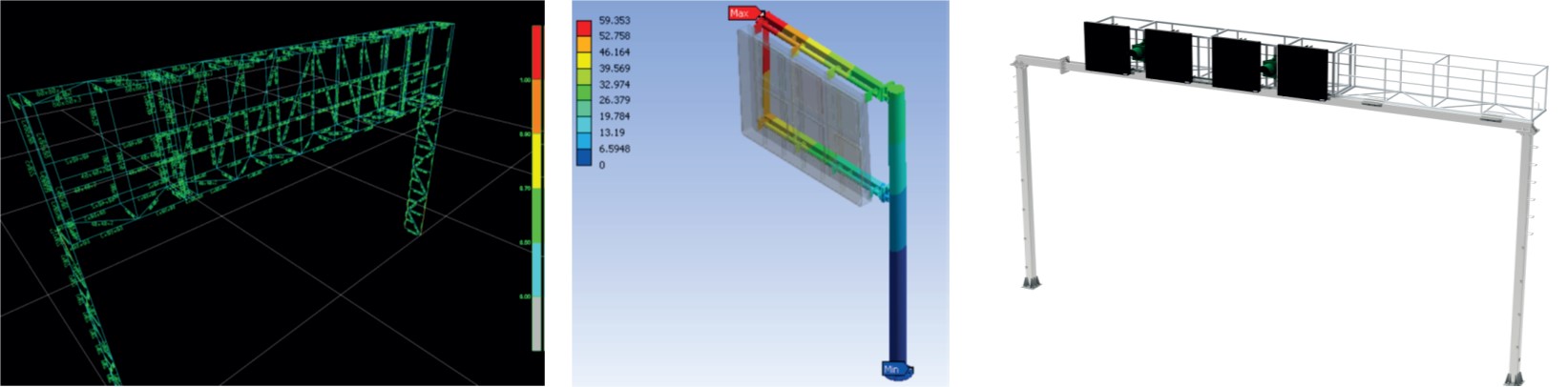

MECHANICAL R&D SKILLS

-

- ANSYS and SAP analysis software infrastructure

- Wind load simulations

- Snow load simulations

- Point load simulations

- Elastification / plasticization status analysis

- Deformation and displacement analysis

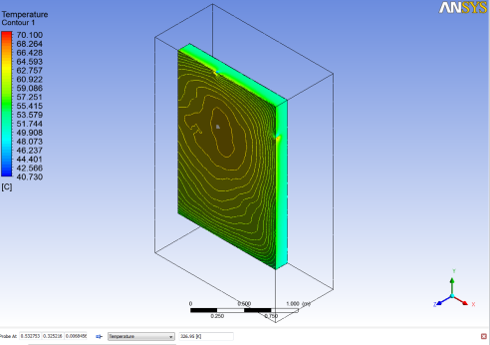

- Heat transfer analysis(Computational Fluid Dynamics - CFD)

- Computer aided 3D design

- 3D rapid prototyping

- Plastic injection parts and mold design

- Plastic melt/temperature flow analysis

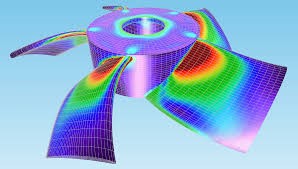

OPTICAL R&D SKILLS

-

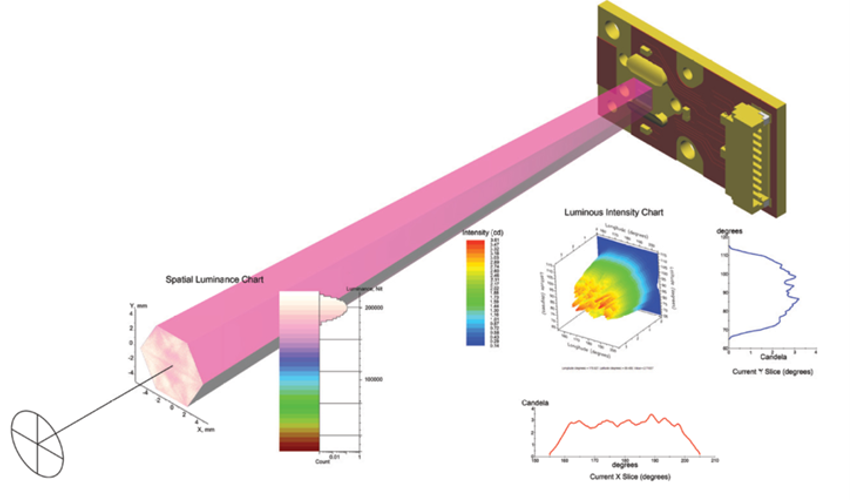

- Non-Imaging Optic (lighting design)

- Signaling signs lighting design

- Ligth pipe design

- Control panel lighting design

- Indoor and outdoor lighting

- Land/sea/aircraft interior and exterior lighting design

- Plastic-optical injection mold design and simulation

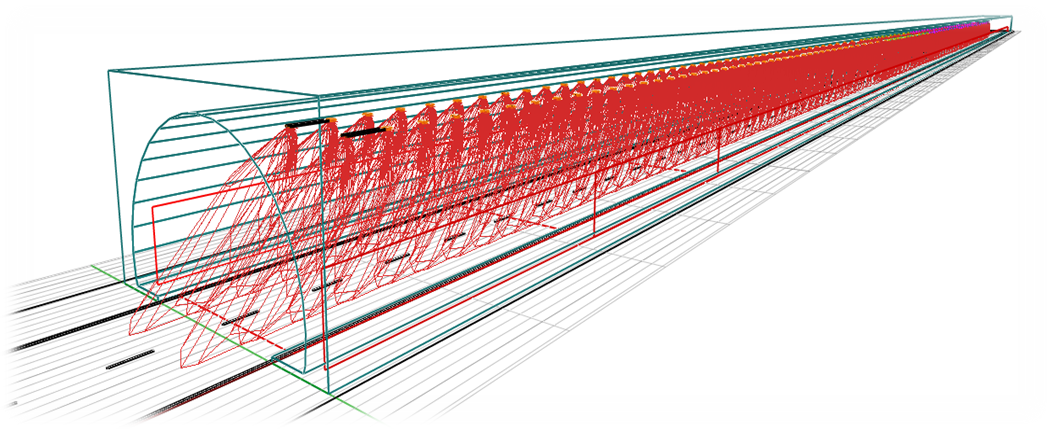

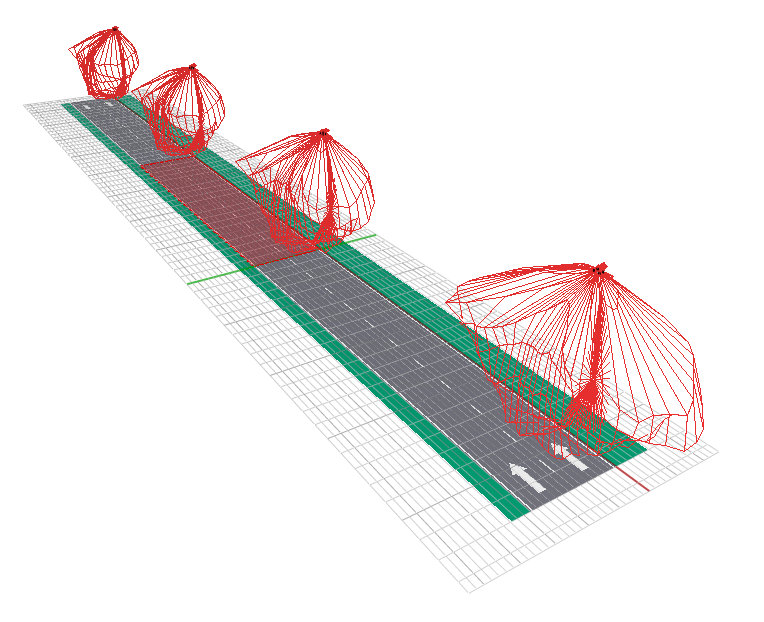

- Road and tunnel lighting design and consultancy services

- Design, simulation, rendering and engineering calculations of all kinds of plastic-optical systems

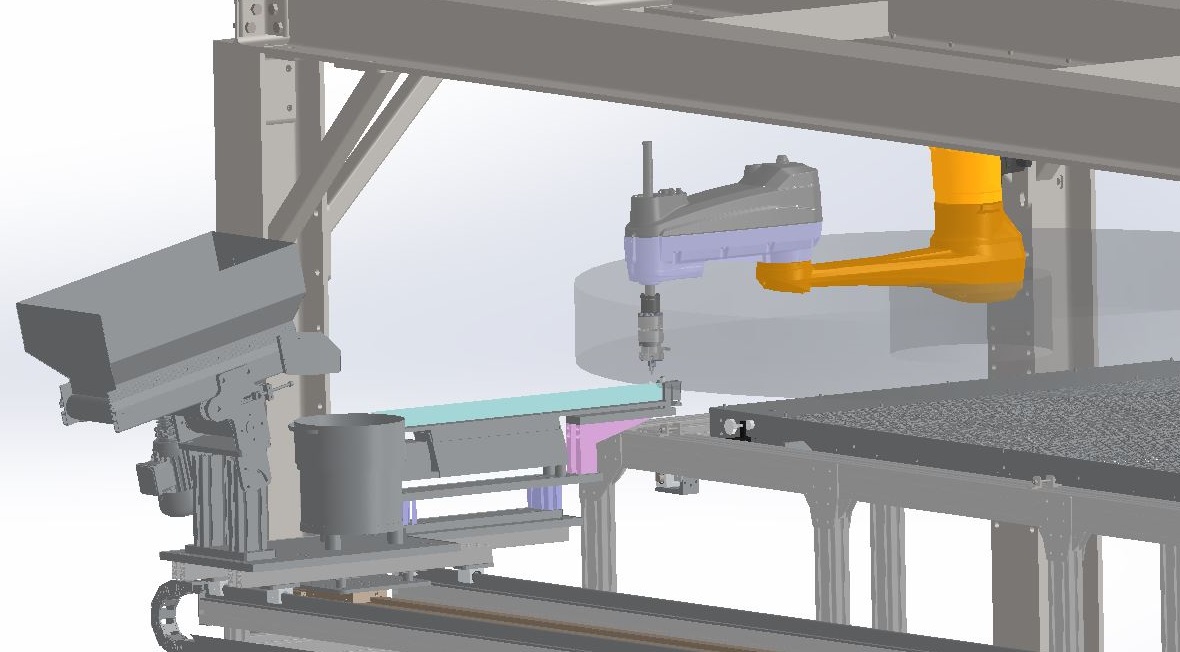

- Robotic automation design, integration and engineering solutions

TEST AND CERTIFICATION SKILLS

Optical Test Skills

-

- Color coordinate measurement

- Spektrum measurement

- Glow test

- Total lumen measurement

- Solar simulation

- Light emission measurement

Environmental Test Capabilities

-

- Water and dust insulation tets

- Impact resistance test

- Corrosion / UV resistance

- Moisture test

- Temperature test

- Paint resistance/aging/application tests

- Ultrasonic welding/joint tests

- Wind tunnel

Electrical Test Skills

-

- Electrical continuity tests

- Leakage current test

- Electrical insulation test

- High voltage test up to 3000 Volts

- AC/DC strength test

PRODUCTION SKILLS

Electronic Production Capabilities

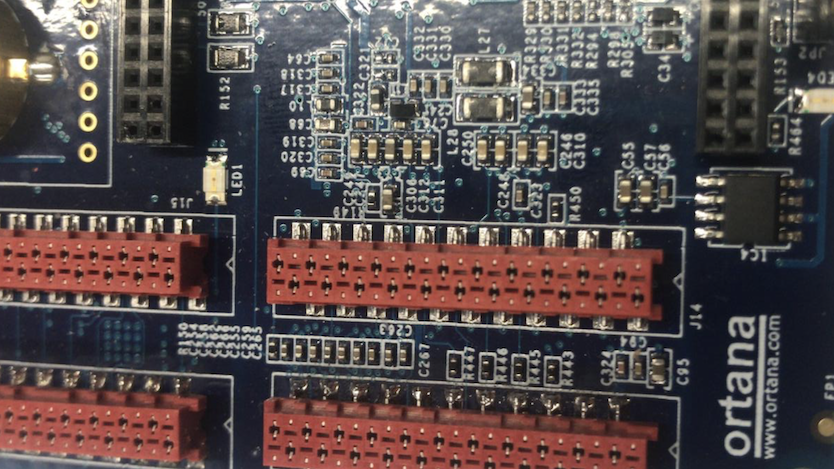

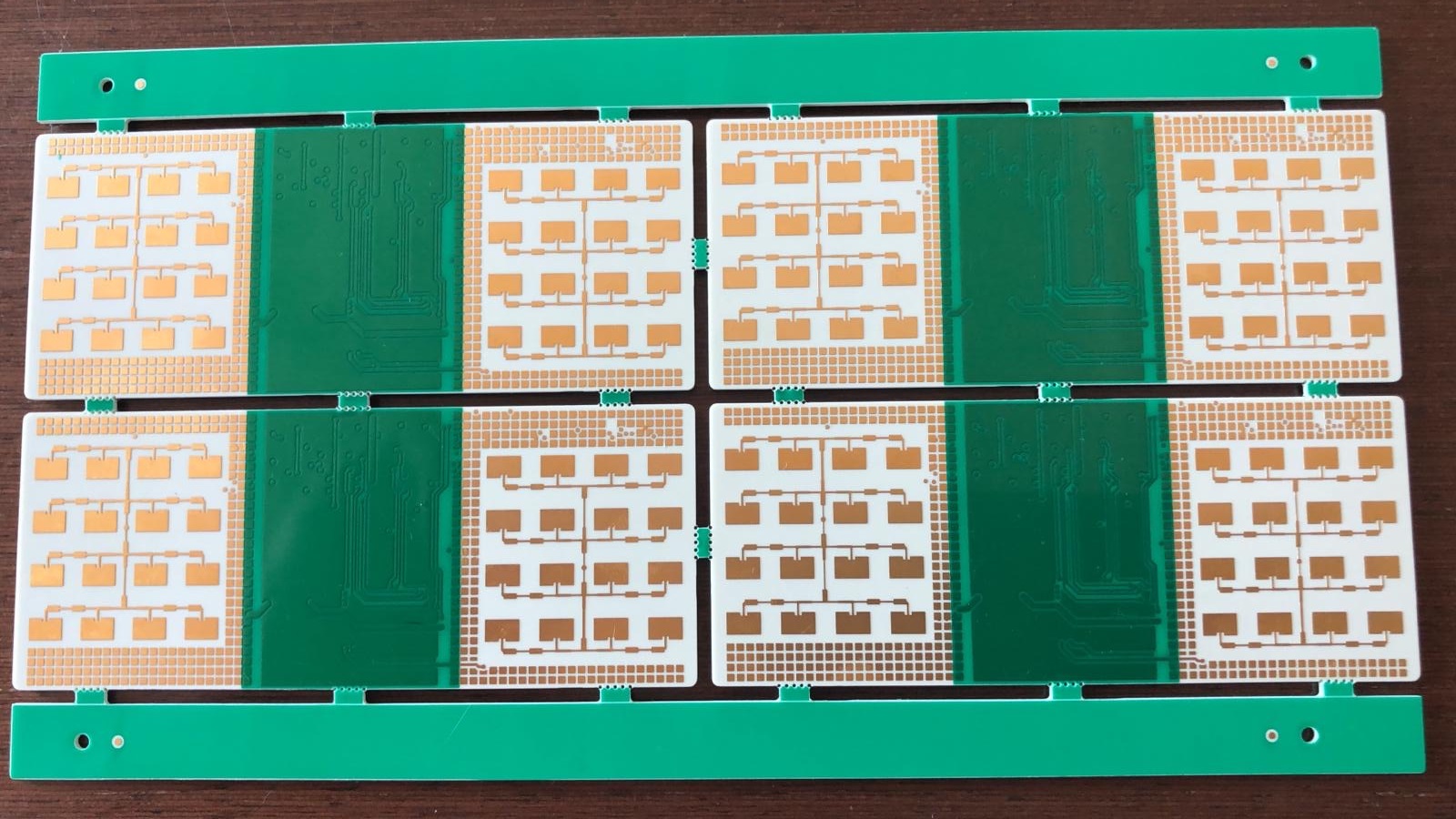

4 Lines, JUKI Based Electronic Typesetting Line

-

- Automatic SMD production machines with high speed and precision

PCB Cleaning / Washing / Coating

PCB cleaning in avionics and space standarts and

PCB conformal coating to work in all kinds of difficult conditions

Production Line in IPC Standarts

Mechanical Production Capabilities

-

- Mechanical plate processing capability

- 4 piece of CNC 20 tons punch machine

Paint and Coting Unit

-

- Metal painting/coating works (Military standarts)

- Alüminum chrome plating

Turkey's one of the high standarts exemplary facilities with the high quality qualicoat standarts

and 1000 m2 painting capacity per day, it is planned to be commissioned in August 2020.

Plastic Injection Production Line

It has the infrastructure of CNC plastic injection machines specially produced for high quality plastic optical applications.

Automated classification and quality control systems based on robotic image processing camera provides quality control at

every point of production.

Owned machine difference is as follows:

- 1 piece of 300 tons injection machine

- 2 piece of 100 tons injection machine

- 1 piece of 50 ton injection machine

CNC Machining and Plastic Injection Production Infrastructure

Ortana has CNC machining equipment machine park for both plastic optical injection molds

and products manufactured at military standarts.

- 1 piece of 4 axis vertical machining center

- 1 piece of 3 axis vertical machining center

- 1 piece of 5 axis C-Y axis double chuck lathe

- 1 piece of 2 axis CNC lathe